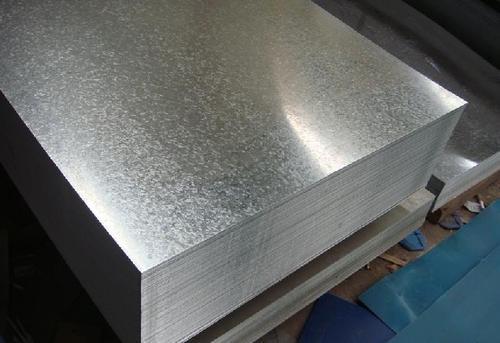

电镀锌层厚度一般在5-12μm,经在铬酸盐钝化处理后,其防腐蚀性能大幅度提高,能抵抗48-96h的中性盐雾试验,因此,镀锌在螺纹紧固件中得到了广泛的应用。

The thickness of electro galvanized layer is generally 5-12 μ m. After chromate passivation treatment, its anti-corrosion performance is greatly improved and can resist the neutral salt spray test of 48-96h. Therefore, zinc plating has been widely used in threaded fasteners.

电镀锌层厚度对镀锌层的质量关系较大,主要表现在:

The thickness of electro galvanized layer has a great influence on the quality of galvanized layer, which is mainly reflected in:

⑴镀锌层的抗腐蚀性能取决于镀层厚度和暴露环境,使用条件越恶劣,需要的镀层越厚,而整个镀层的抗腐蚀性能又取决于镀层的最薄弱部分包括局部厚度最小的地方的抗腐蚀能力。

⑴ the corrosion resistance of galvanized coating depends on the coating thickness and exposure environment. The worse the service conditions are, the thicker the coating is required, and the corrosion resistance of the whole coating depends on the corrosion resistance of the weakest part of the coating, including the place with the smallest local thickness.

⑵锌层过厚的地方容易出现粗糙、结瘤、脱落等疵病。

⑵ where the zinc layer is too thick, defects such as roughness, nodulation and falling off are easy to occur.

⑶锌层过薄的地方,光泽度差,发暗、发雾,在出光、钝化的过程中容易露底。

(3) where the zinc layer is too thin, the gloss is poor, dark and foggy, and it is easy to expose the bottom in the process of light and passivation.