如何防止不锈钢彩色板焊接时变形

How to prevent deformation of stainless steel color plate during welding

1、严格控制不锈钢彩色板焊接接头的热输入“选择合适的焊接方法和工艺参数,主要是焊接电流、电弧电压和焊接速度。

1. Strictly control the heat input of stainless steel color plate welded joints "select appropriate welding methods and process parameters, mainly welding current, arc voltage and welding speed.

2、不锈钢花纹板供应商焊接一般采用小喷嘴,但建议尽量使用大喷嘴口径,使焊接时焊缝保护面更大,长时间隔绝空气,使焊缝成型更好特性。

2. Stainless steel checkered plate suppliers generally use small nozzles for welding, but it is recommended to use large nozzle diameter as far as possible to make the weld protective surface larger and isolate the air for a long time, so as to make the weld forming better.

3、铈钨棒φ1.5,磨削的锋利度要高一些,钨棒伸出喷嘴的长度尽量长,这样会使母材熔化更快,即熔化温度上升较快,温度较集中,因此,可以在不提高母材温度的情况下尽快熔化需要熔化的位置。这样,材料中应力变化的区域就会变小,Z终会减少不锈钢彩色板材料的变形。

3. Cerium tungsten rod φ 1.5. The sharpness of grinding should be higher. The length of the tungsten rod extending out of the nozzle should be as long as possible, which will make the base metal melt faster, that is, the melting temperature rises faster and the temperature is concentrated. Therefore, the position that needs to be melted can be melted as soon as possible without increasing the base metal temperature. In this way, the area of stress change in the material will become smaller, and Z will eventually reduce the deformation of stainless steel color plate material.

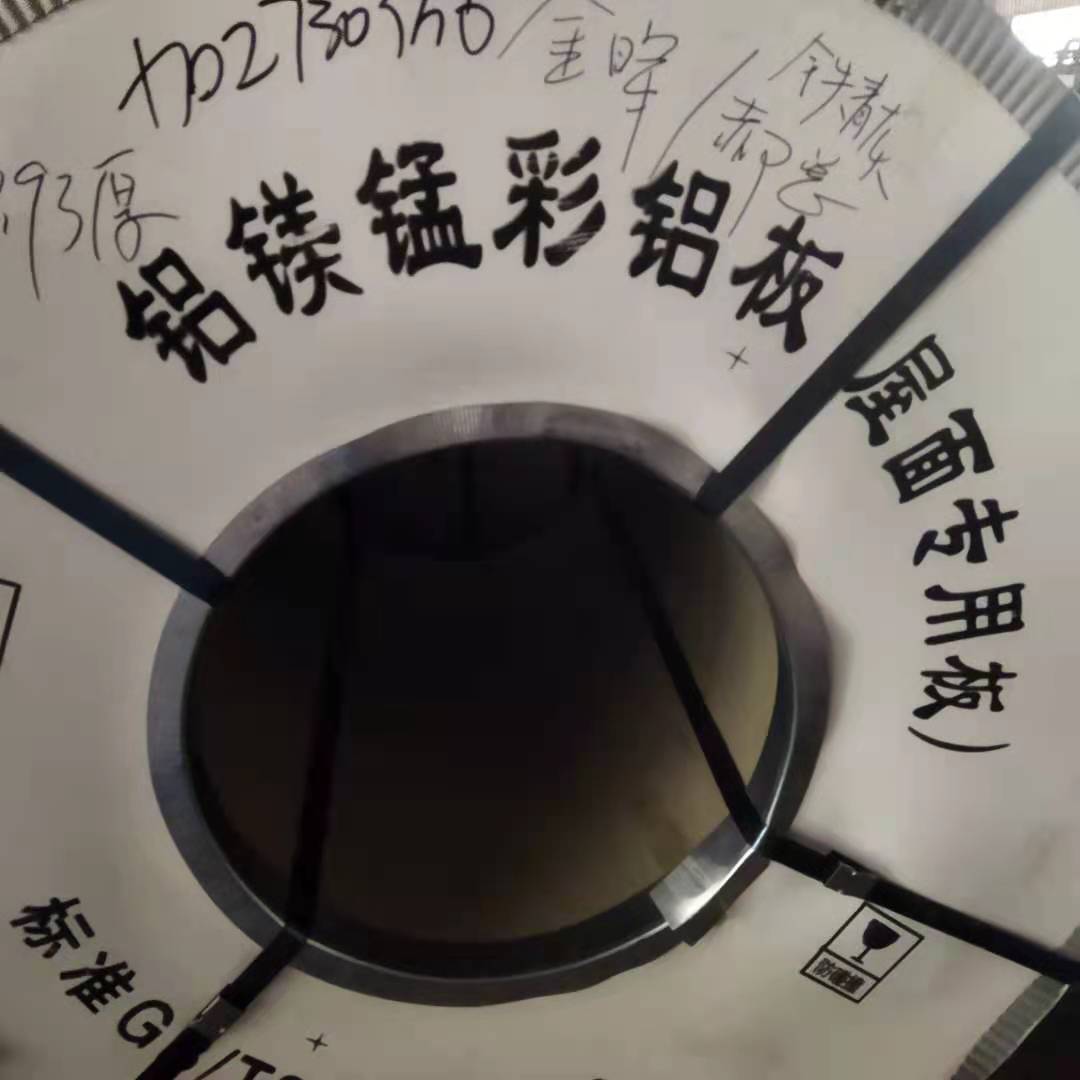

彩色不锈钢加工技术,从工艺上看,有化学法和电化学法。它们可以在特定的电解液中处理以获得不同的颜色,从而提高不锈钢的耐磨性、耐腐蚀性和颜色多样性。不锈钢花纹板报价用于不同的场合,获得不同的经济效益。

Color stainless steel processing technology, from the process point of view, there are chemical method and electrochemical method. They can be treated in specific electrolyte to obtain different colors, so as to improve the wear resistance, corrosion resistance and color diversity of stainless steel. The quotation of stainless steel checkered plate is used in different occasions to obtain different economic benefits.

有色不锈钢的制作方法有以下几种:1、高温氧化法;2、化学氧化法;3、电化学氧化法;4、离子注入法。

The manufacturing methods of non-ferrous stainless steel are as follows: 1. High temperature oxidation method; 2. Chemical oxidation; 3. Electrochemical oxidation; 4. Ion implantation.

各种处理方法总结如下:

Various treatment methods are summarized as follows:

1、高温氧化法是将工件浸入特定的熔盐中,并保持一定的工艺温度和时间,使工件形成一定厚度的氧化膜,呈现出各种颜色。

1. High temperature oxidation method is to immerse the workpiece in specific molten salt and maintain a certain process temperature and time to form a certain thickness of oxide film and show various colors.

2、化学氧化法是通过控制温度和时间,在特定溶液中形成各种膜色。

2. Chemical oxidation method is to form various film colors in a specific solution by controlling temperature and time.

3、电化学法是通过控制温度、电压和时间,在特定的电解液中形成一定厚度的氯化膜颜色。这种工艺比较成熟,应用广泛。

3. Electrochemical method is to form a certain thickness of chloride film color in a specific electrolyte by controlling temperature, voltage and time. This process is relatively mature and widely used.

4、离子注入法在真空中蒸发离子,使离子沉积在不锈钢表面。比如市面上的表壳,金色的表带就采用了这种技术,适合大批量生产。

4. Ion implantation evaporates ions in vacuum to deposit ions on the surface of stainless steel. For example, the watch case and gold strap on the market adopt this technology, which is suitable for mass production.

本文的精彩内容由不锈钢花纹板提供知识提供,本网站还有很多的精彩内容,更多的内容您可以点击进入:http://www.sdcgy.com我们有专门的客服为您解答问题

The wonderful content of this article is provided by stainless steel checkered plate. There are many wonderful contents on this website. You can click to enter more contents: http://www.sdcgy.com We have special customer service to answer your questions